Abstract:

The paper unfurls the contribution of the Vishwakarma community to Indian metallurgy. The lost-wax technique is an age-old casting technique followed by many ancient cultures and in India it can be traced back to the Harappan culture. It is a method in which hot metal is poured into the wax model which is lost during the process.

The paper highlights the ancient process of the technique through literature reviews like Mānasollāsa, Mānasāra and Śilparātna and also through ethnographic parallels. Tamil Nadu and Kerala have been chosen for the purpose, where the traditional method of the lost-wax technique is practised by the artisans (Vishwakarmas). The first author hails from the Viswakarma community in Tanjore district in Tamil Nadu. Hence documentation of the art and science of bronze sculpture technology was conducted in his family workshops at Tanjore and Mamallapuram in Tamil Nadu. The second author had conducted ethnographic surveys in many parts of India where the lost-wax technique is practised for her doctoral research. Both the authors will also look into the archaeological aspect of the Vishwakarma community and their role in ancient metallurgy. The role of regional variation in between the two states; intricate details that are unique to the particular region/workshop will also be focused on by both the authors.

Introduction:

The tradition of the lost-wax model in India goes back to Harappan cultural times and the finest example is the dancing girl. The tradition is continued even today in various parts of India such as Tamil Nadu, Kerala, and West Bengal.

The word bronze comes from “Brindisi”, the name of a small town and port on the Adriatic coast of Italy which had always been famous for its bronze image. The Latin ‘EsBrundusium (From Brindisi) subsequently becomes bronze’ (Kuppuram 1989). In India, metal icons find a very special place in the temple as well as within domestic shrines across the country (Udayakumar 2011). South India bronze sculptures are well known for their artistic excellence.

Lost-Wax Casting Technique:

Lost-wax casting (also called “investment casting”, “precision casting” or Cire Perdue in French) is the process by which a duplicate metal sculpture (often silver, gold, brass or bronze and copper) is cast from an original sculpture. Depending on the sculptor’s skills, intricate works can be achieved by this method. The method of manufacturing an object starts when the artisan designs the desired shape for an object.

Archaeological Evidence of Lost-Wax Casting Technique:

This technique was employed in antiquity for making gold, silver ornaments. Examples that can be cited are the famous Dancing Girl of Mohenjo-Daro, Daimabad Bronzes and also a pendant has been found at the site of Kuntasi, Gujarat which is made by hollow casting method of lost-wax technique.

Historical Pieces Of Evidence Of Lost-Wax Technique:

The antiquity of bronze sculpture dates back to the Indus civilization (Bandopadhyay 1987) or Chalcolithic period but it develops as an independent school of art during the classical period of the Pallavas, Cholas and the later dynasties of South India (Udayakumar 2011). In terms of understanding the casting process for producing a metal image, the earliest evidence in South Asia is seen in the Lost‐wax technique for the bull and dancing girl of Mohenjo‐Daro dated to around 2500 B.C (Bandopadhyay 1987). Over the past millennia Indian metal workers have made a breakthrough in the field of metallurgy. They succeeded in producing brass, which looks almost like gold. This was achieved by fusing zinc and copper (Agrawal, et al. 2010).

Another early specimen of metal art in South India is of a Chola period mother goddess figurine in bronze discovered at Adichanaullar in Tamil Nadu (Nagaswamy 2003). Bronze images produced by the lost‐wax technique have been discovered from several places in South India dated between 750 A.D‐1100 A.D (Sivaramamurti 1963). This timeframe includes the Cholas (846‐1216 A.D), who succeeded the Pallavas in the middle of the ninth century and promoted temple building activities in the region (Sivaramamurti 1962; Mehta 1971). Indian metal sculpture in South India mostly flourishes during the Chola period, but there are some specimens discovered having a high aesthetic and technical quality belonging to Pallavas ruling from Kanchi. For example, a Nataraj sculpture which belongs to the 8th century A.D., Kuram, District Chinglepet, (Government Museum, Madras) (Sivaramamurti 1962; Mehta 1971). Another fine Pallava sculpture Tripurantaka, 8th century A.D., locality unknown, (Gautam Sarabhai Collection, Ahmedabad). This is one of the finest examples of Pallava representation of Siva (Sivaramamurti 1962).

The medieval icons of Southern India which are among the most acclaimed Indian artistic innovations are those of the Cholas (9th ‐10th centuries). The most important phase of metal sculpture, especially the icons which flourished down south from the Tungabhadra river to extreme southern sometimes in the 10th‐11th centuries under the Chola of the Vihayalya line, ruling from Tanjore (Sivaramamurti 1962). Best known in Hindu iconography are representations of the dance of Siva which also captured the imagination of master sculptor Rodin (Kuppuram 1989; Srinivasan 1998). The early Chola epigraphy records the gift of images made by the emperors to the temple for worship “ghanamagaelundaruluvittachandisvaraparsadadevar” i.e., the god chandisvaraprasadadeva cast solid and set up and “ghanapollalagachcheydarishabham” i.e., is bullcast hollow (Kuppuram 1989). Several images are mentioned in the temple inscriptions of Tanjore. These specify that the principal image was cast as a solid object, while animals and pedestals could be hollow. Some important sculptures include the Somaskanda sculpture, early Chola 9th century A.D., Tiruvalangadu, District North Arcot, (Government Museum, Madras), a representation of Chandikesvara the steward of Siva’s household, of the 11th century A.D., Velankanni, District Tanjore, (Government Museum, Madras), (Sivaramamurti 1962), a mother and child sculpture representing Krishna and his foster‐mother, Yasoda, late Chola 13th century A.D., Thogur, District Tanjore Government Museum, Madras (Sivaramamurti 1962).

Literary Sources:

In the second century B.C Patanjali in his Mahabhashya, an exposition of Panini’s works gives a vivid picture of the artisans in the village. The Upanishads, Manusamhita, Yajnavalkya Samhita and Harivamsa also provide information on the casting method (Jafar 1988). The Agnipurana, Matsyapurana of the Gupta period (4th to 6th century AD) provides a detailed description of the technique of casting bronze images (Ruth 1962).

The Tamil and Malayalam versions of the Silpasastra are being used today as technical manuals by metal icon makers of Madras and Kerala (Krishna 1976). The Vedas, the Ramayana and Mahabharata also refer to casting art of bronze, silver and gold (Ruth 1962). The Rig Veda refers to the word Ayas meaning different metals, Viz. Syama, Ayas (iron) and Lohitaayas (Copper or bronze) (Ruth 1962). The casting method is known as the Madhuchista‐vidhanam. Madhuchista means bee’s wax. This method is referred to in detail in Sanskrit texts like Manasara, silparatna and Vishudharmotta (Ruth 1962). This method is well known as Cire‐Perdue or Lost‐wax method in the west (Sivaramamurti 1962).

The term Sthapathi is used in many of the ancient literature which means chief craftsman who engage themselves in the making of religious icons and images. They belong to the Karmakar or Viswakarma community which practices various other crafts such as goldsmithing, blacksmithing, coppersmithing and stone carving (Krishnan 1976). In Tanjore District, there are traditional families of the Viswakarma community who have a tradition of making bronze sculptures. In casting bronze, tin is alloyed to harden copper. Most bronzes in antiquity are cast low‐tin bronzes with a tin content that is within the limit of formation of the face-centred cubic (fcc) solid solution (Srinivasan 1998).

Situating The Vishwakarma? The Artisans And The Craftsmen (Ramaswamy 2004):

The socio-economic status of the Vishwakarma as a collective body, as well as the differentiation and stratification that existed among them depended upon the nature of their function, which in turn was linked to their physical location. It would be erroneous to treat craftsmen as a monolithic unit, despite their banding together as the ‘Vishwakarma.’ The distinction between an artisan and a craftsman may seem fuzzy because of the shifting nature of their occupations, but it is nevertheless important to make this distinction. Unless one is aware of the complex layers that shaped craft development in early medieval India, one may impose one’s own teleological vision, as did the ‘Orientals,’ the ‘Imperial’ or the ‘Marxist’ historians, by imagining the medieval craftsman as a static, immobile figure enmeshed within a ‘honey-combed’ caste structure. One of the ways of dismantling this discourse is to look at the producers of craft objects as distinct from the producers of purely utility commodities. Is the man routinely laying brick or being employed as a workman in the construction of a dam, an artisan or a craftsman? Would the hereditary maker of ploughs in a village have the same position in economy and in society as the icon-maker? In the context of medieval Peninsular India, it can be said that artisanal skills and craftsmanship came to be differentiated economically in terms of the very different dynamics that affected them. Inscriptional evidence clearly indicates that they represented two different kinds of economies, both of which existed parallel to each other. While the maker of ploughs would exist in the village community with a certain degree of relative physical immobility, socio-economic security and comparatively static living standards, the Kammalar or Panchalar craftsmen who had moved out of the custom determined ‘local’ market would band together as the Vishwakarma. Benefiting from the temple economy and an expanding clientele, the temple-town-based craftsmen would be more mobile and have greater opportunities for improving their income, while also facing greater risks. The risks would primarily arise from the withdrawal of patronage, or the decline of temple centres with the fall of dynasties, as happened in the twelfth and thirteenth centuries with the decline of the Chola State. This situation happened yet again with the fall of Vijayanagar in the sixteenth century. Thus it can be said that while every craftsman was an artisan, every artisan was not a craftsman, the principal distinction arising from their differing relationships to the medieval economy, both in terms of location and of function. More particularly on the latter count, the artisan differed quite significantly from his urban counterpart. To give an example, even among the goldsmiths there were two distinct hierarchical categories. At the lower level was the small-time tat tan or goldsmith who worked on a piece-wage and lived at the subsistence level, catering to a custom-determined market. These goldsmiths can be seen even today in South India, sitting at street corners and eking out a living by repairing chains or other ornaments, and piercing ears and noses (a must for women and female children among many South Indian communities). At the higher level was the great goldsmith referred to in the inscriptions as perum tattan (literally, ‘great goldsmith’) indicating master-craftsman employing apprentice goldsmiths, catering to a fairly wide market and forming a part of the urban establishment (Vijaya Ramaswamy 2004).

Statement Of The Research Problem:

The lost-wax technique is an age-old technique of casting practiced by many ancient cultural people. Known to very few people at present about the continuity of the technique it forms our intangible heritage, yet it is deprived of any limelight. Therefore, it was one of the objectives of the authors to highlight the continuity of such an age-old technology even today. Some of the questions that were addressed in this paper are:

- Is this technique really old? If so when is its anecdote?

- Is there continuity or break in the technology?

- The role of Vishwakarmas found enhancing the technology?

- Are there any literary shreds of evidence indicating the role of Vishwakarmas?

Methodologies:

The methodologies adopted for this paper are the following:

- Archaeological Sources from the excavated context.

- Literary sources which include Mānasollāsa, Mānasāra and Śilparātna Ethno-archaeological and ethnographical approaches.

Ethno-archaeological Approach:

Ethno-archaeology can be defined as the study of the relationships between human behaviour and their archaeological consequences in the present. It is concerned with the investigation of the material culture and built environments of living people, concerning the processes that affect and affects their conversion to archaeological context (Lane, 2006: 402).

The archaeological evidence of lost-wax techniques from the excavated sites is found in form of mainly finished products or miscast products which have been discarded by an artisan (and will be re-casted). The famous Dancing Girl of Mohenjo-Daro, Daimabad Bronzes, a pendent from Kuntasi (as reported by excavator Dhavalikar) all exemplifies the fact of the skilled craftsmanship of the Harappan cultural metalsmith. However, the archaeological records do not sustain all the evidence of the processes of lost-wax casting. Therefore, the missing link between the archaeological record and the process of that casting technique can be fulfilled through field examinations of the living parallels practising the age-old traditional method of the lost-wax casting technique (Mukherjee 2021).

Ethnographical approaches (Case Studies):

Two case studies from two different states have been undertaken to understand the technology as well as the role of Vishwakarma. In this paper, we will point not only to the technology of a craft and how it is intricately associated with craftsmen but also the regional variation that is an integral part of any craft activity

Figure 1: Google image showing the study area

The Ethnographical Approach I – Bronze Sculptures of Tanjore, Tamil Nadu:

Measurement of Bronze Sculptures

Most icons are still cast by traditional ways well known as Cire‐Perdue. Mānasara is one of the ancient texts dealing with the lost‐wax technique. Chapter LXVIII deals with the process of lost‐wax methods termed Maduchchhista Vidhanam. Measurement plays an important role in Indian iconography. A fundamental concept in Indian cosmology has been the maxim that to measure is it creates (Krishnan 1976; Ruth 1962). Measuring of form is also expressed as early as in the Rig Veda (Ruth 1962). This measuring of forms is still followed by all families traditionally involved in these practices. According to the textual analysis of measurement, the point for each section has to be organized properly. Below are listed these prescribed units for arriving at the correct proportion of a God (Ruth 1962; Ganapati Sthapathi 2001).

The top of the headdress occurs as a system point only in the Pratimalaksanam, which includes the Usnisa of the image. The meaning of Tala is the length of the palm. The system is based on a unit Tala which is the norm of measurement from where the hairline meets the forehead to the tip of the chin (Ganapathi Sthapathi 2001).

Technical Process Of Casting Bronze Sculpture in Tanjore:

The technique of casting by the Cire‐perdue process can be divided into four principal stages, they are:

- Model Making:

Preparation of wax

Figure 2: Wax Model Making

- Mould Making:

Preparation of fine clay and other materials

Figure 3: Preparation of Mould

Figure 4: De‐Waxing

- Melting and casting metals:

Preparation of alloy

Figure 5: Casting

- Chiseling and finishing:

Figure 6: Removing the Buried Clay

Figure 7: Chiseling and Engraving

Polishing

The sculptor takes note of the Talas as prescribed in the Silpasastra (Sivaramamurti 1962). For image making the sculptor takes a coconut leaf cut into the required image height and folded the different lengths in proportion to the length of various parts of the image based on the Tala.

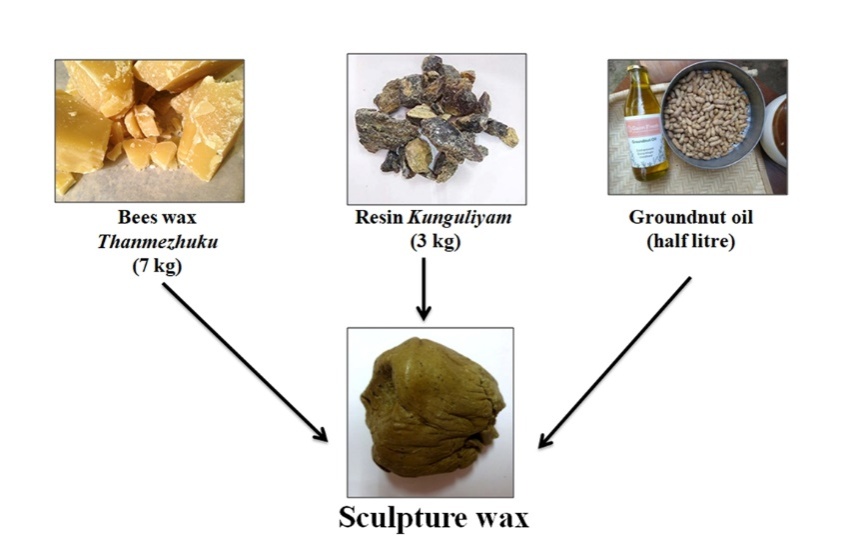

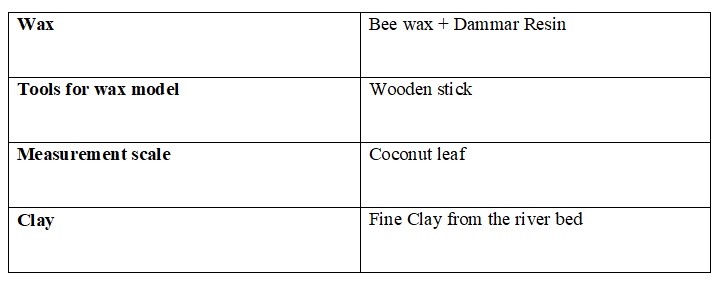

Preparation Of Wax:

Wax has to be prepared by mixing pure beeswax, resin from the dammar and ground oil, in a proper portion of 5:5:1. Resin has to be ground into powder and heated till thick liquid forms. After this, it is added to the beeswax and stirred with a stick till it liquefies and is well mixed. After the wax melts, the liquid is filtered through a white cotton cloth into a tank containing cold water, thus allowing it to solidify. This is then used for making the wax model.

Preparation Of The Wax Model:

In fashioning the wax model, parts of the image such as the head, body, legs, etc. are made separately by hand. These are then refined by warming them and shaping them using a knife and scraper. Finally, the different finished parts of the image are jointed together using heated iron tools. In the case of making a small bronze image, the pedestal is shaped as part of the wax model itself, but in the case of large models, the pedestal has to be made separately.

Mould Making:

The method of moulding includes different types of moulding media and their preparation, e.g. hard clay, semi-hard clay and soft clay. In the case of the small image, only three layers of clay are required but for large images, more layers are required. The clay which is sourced from the river bed of the Kaveri is locally called ‘Vandal man’. During the application of clay, the wax model has to keep either on a piece of paper or a white cloth.

- Soft‐clay: For preparation, four parts of well levitated which is used for making pottery and one part of ordinary clay is mixed.

- Preparation of very soft clay: Soft clay is mixed with cow dung until it becomes extremely soft.

Method Of Moulding:

The fine clay has to be applied evenly to the wax mould. After it is dried, soft clay is applied over it and it is dried again. After it is fully dry, hard clay is applied and the same is bound with an iron strap. Clay is again applied over this until the mould is strong and satisfactory. Caution should be taken that the iron strap should pass through less important parts of the object.

De‐waxing The Mould:

After the mould is dry, it is placed over firewood and baked, till the wax melts completely and flows out. Once the wax is removed, the mould is removed from the fire and placed in a pit with the mouth facing upwards.

Melting And Casting Metals:

In South India, five metals were used for the production of the idols which is called “Panchaloha” (Kar 1952; Ruth 1962; Krishna 1976). These include a mixture of copper, silver, gold, brass and tin. The rule used by the sculptor to estimate the weight of the alloy occupying the mould cavity is that it should be normally 8 times the weight of the wax model. For melting the metal, coke or charcoal are used. When the metal and mould temperatures are proper for casting, the mould is placed horizontally in a slightly slanting position over bricks. The stone should be avoided for this process. While pouring the metal liquid into the mould, cup-shaped bricks are held below to avoid mishaps. To avoid entry of impurities like charcoal floating on the surface of the molten metal, while pouring metal into the mould, a piece of knitted jute cloth covers the mouth of the crucible. After completing the casting process, the mould is allowed to cool for a day.

Removal Of The Buried Clay:

The sculptor carefully removes burnt clay to extract the object. Iron rods and wires are removed and the sculptor removes all unwanted runners in the bronze idol/object. The image now is exactly that is seen in the wax model. Details of the dress and ornaments as well as other final touches are essential to make the icon perfect in all aspects. These aspects are added at the later stage. The smoothing of the image is done using fine grade emery paper.

According to the tradition, by way of polishing, the image is cleaned with tamarind and soapnut water and scrubbed with a copper brush. Here the author would like to illustrate the aspects of continuity of bronze casting tradition in Tamil Nadu, through his survey of workshops in Tamil Nadu and experimental work. This table shows the materials which are used for ages.

The sculptors are still continuing to use these through ages without any change and these materials are the basic requirement to make an image. This shows that continuity is preserved by our ancient and modern sculptors of Tamil Nadu. Even the author did experimental work of making sculptures using traditional materials which cannot be replicated by using any other modern materials.

The sculptors are still continuing to use these through ages without any change and these materials are the basic requirement to make an image. This shows that continuity is preserved by our ancient and modern sculptors of Tamil Nadu. Even the author did experimental work of making sculptures using traditional materials which cannot be replicated by using any other modern materials.

Ethnographical Approaches II – Brass Sculptures of Mannar, Kerala:

Ethnographic surveys have been conducted in the workshops area of the Mannar region. The work documented has been carried out by the author herself as an approach to understanding regional variation in the application of the lost-wax casting technique. In South India, this particular technique is applied to manufacture sculptures. The process is cited as below:

Raw material:

The same process is followed for the lost-wax technique all over India considering regional variation. A mixture is required to make sculpture wax (since it is not available in the market) which is used for wax modelling in South India for the lost-wax technique. Mixture composition of wax defers in each region (particularly the sculptors decide the proportions according to need), but in general the consistency that followed is resin 85%, yellow wax 15% and oil (coconut oil is preferred) 250 ml. Oil is used to increase the elasticity. The wax preparation takes 4-5 hours to complete. The mixture has to be boiled at around 800 °C and then with the help of a strainer it is purified and the purified mixture is left to cool and when it becomes leather hard (in between fluid and solid) it is used for wax preparation (Mukherjee 2021)

Fig 8: Raw Material/Wax Preparation

Preparation Of A Model:

Making a replica of the object with wax (beeswax) is the first of the technology. The artisan first makes the desired shape of the object in wax. In wax preparation, regional variation can be found. Wax is heated continuously and while it is being heated a small proportion is taken and kneaded and given the shape. It is to be noted that wax model cannot be prepared if the wax becomes cold. The model is made by considering proper measurements such as the length of the object, the thickness of each part, etc. The preparation of the model is the same in any lost-wax casting technique (Mukherjee 2021).

Preparation Of Mould:

Once the wax model is ready, clay is added to the wax model. Three-four layers of clay are added to the model. These layers are made of fine, medium and rough clays. Alternate layers of these clays are applied to strengthen the mould for casting. Clay is prepared in amni (local term for saddle quern). After preparing the moulds they are sun-baked till are dried completely. Complete preparation of moulds takes a week. The next step is sticking the pot shreds to the model. This is to support clay to hold along the mould. This feature is also an example of regional variation (Mukherjee 2021)

Fig 9: Preparation of Mould

De-waxing:

The mould is heated to melt the wax to create hollowness. This process is known as de-waxing. Molten metal is poured into the hollowness and the casting process begins.

Casting:

Before the molten metal is poured into the mould, a pit is dug. In the pit, the moulds are buried keeping the runners and raisers project. The molten mould is poured through these. The mould is allowed to cool down and is taken out from the pit the next day. Hereafter, the mould is heated. They are heated for more than an hour. The next step is the melting of brass/ Bronze. Brass/ Bronze are melted in a crucible. Then they dig a pit and cover the mould with the soil only keeping runners and raisers projectile. Molten metal is poured into the mould.

Fig 10: Casting

Breaking Of mould:

Moulds are reused, in the sense that the moulds are broken, and those broken parts are recycled. Broken parts are ground to a fine powder and those are coated to the wax model (Mukherjee 2021).

Fig 11: Breaking of Mould

Polishing:

Finally, the object is chiselled, making designs and polishing (Mukherjee 2021).

Fig 12: Polishing

Final product:

The product is ready to be sent to market for selling (Mukherjee 2021).

Furnace:

The artisans of Mannar use two furnaces at the same time to speed up the process. One is square-shaped and fitted to heat crucible with brass and another is circular to accommodate moulds. Fuel used is coconut shells to heat mould which provide steady temperature and charcoal for crucible heating which usually consumes high temperature. Crucible and tools used by the craftsmen are identical (Mukherjee 2021).

Discussion:

It is of great importance that India still preserves the traditional methods of bronze image-making with various developments in techniques used. This continuity in traditional methods enables us to investigate variability in the development of these techniques which began with the Indus Valley Civilization and continued through the Pallava and Chola periods. In particular, the town of Tanjore was and still is an important centre for the manufacture of such images, right from the 10th and 13th centuries onward, when craftsmen settled here under the royal patronage of the 9th century onwards. The technique and method applied by ancient sculptors are still practiced by their descendants. They have preserved traditions and take strenuous effort to produce images of great artistic merit and skill and in this practice, they follow the style and convention laid down in the ancient texts to which they add their creativity and imagination. In the context of archaeology, what is of great importance is that studies of traditional procedures of bronze casting aids in interpreting such techniques from artefacts and features found in the archaeological record. It is of great importance in identifying specific types of instruments used for manufacture as also variations like furnaces and waste, etc. obtained.

This paper encloses the experimental study of the lost‐wax technique conducted by the first author in his workshop in Tanjore district, Tamil Nadu. The way of preparing wax, casting etc. is the same process but with little technical development. For example, in ancient times the sculptors used rivers bed clay for soft moulding but in the present time, the sculptor is using plaster. The change in the raw material or development of technology has many advantages and disadvantages. In ancient times mostly locally available raw material was used but due to modern technology imported raw material is also used in the preparation of the images. Even though some modern techniques are used in idol manufacturing, by and large the concept and production follow the traditional methods and the traditional Lost‐wax technique used in South India is one such example. The major contribution of this work is that it shows a continuation of bronze technology within the families and the whole family is involved in the work. In the modern era of machine production this particular art of bronze production is dying out very fast and in a few years, traditional manufacturing will come to an end. The major aim of this work is to make people aware of its legacy and importance and to create social awareness among the people and future generation as well as to keep the tradition of Lost‐wax techniques before it is lost.

References:

Agrawal, S.C., Swaeup and Annop (Eds.). 2010.Indian Civilization through the millennia. New Delhi: Excell Publication.

Bandyopadhyay, B. 1987.Survey of Indian metal sculpture. Delhi: Sundeep Prakashan.

Ganapathi Sthapathi, V. 2001.Shilpanul. Chennai: Tolli Nuupa Eyakam.

Kar, Chintamoni. 1951. Indian metal sculpture. London: Alec Tiranti Ltd.

Krishna, M. V. 1976. Cire Perdue casting in India. New Delhi: Jayant Baxi for Kanak.

Kuppuram, G. 1989. Ancient Indian Mining, Metallurgy and Metal Industries,

Volume I. Delhi: Sundeep Prakashan.

Mukherjee, Diya. 2021. Copper-Bronze Technology of the Harappan Culture in Haryana and Gujarat. Unpublished Thesis. Pune: Deccan College Post Graduate and Research Institute.

Muhmud, S. J. 1988. Metal technology in Medieval India. Delhi: Daya Publishing House.

Nagaswamy, R. 2003. Facts of South Indian Art and Architecture. New Delhi: Aryan

Books International.

Rao, S.R. 1979. Excavation at Lothal (1955‐62). New Delhi: Archaeology Survey of India.

Rustam, J. M. 1971. Masterpieces of India Bronze and Metal Sculpture. Bombay

Taraporevala Sons and Co. Private Ltd.

Ruth, R. 1962. Cire Perdue Casting in India. New Delhi: All India Handicrafts Board,Ministry of Commerce and Industry, Government of India.

Sivaramamurthi, C. 1962. Indian Bronze. Bombay: Marg Publication.

Sivaramamurthi, C. 1963. South Indian Bronze. Bombay: Lalitkala Akademi.

Srinivasn, S. 1998. The Use of Tin and Bronze in Prehistoric Southern Indian Metallurgy. Archaetechnology: 44‐49.

Udayakumar, S. 2011. Traditional Wisdom and Current Practices of Bronze Technology in

Tamil Nadu; with Special Reference to Tanjore District. Unpublished M.A. Dissertation. Deccan College Post‐ Graduate Research Institute, Pune.

Vijaya Ramaswamy. 2004. Vishwakarma Craftsmen in Early Medieval Peninsular India. Journal of the Economic and Social History of the Orient. 47 (4), 548-582.

Feature Image Credit: istockphoto.com

Watch video presentation of the above paper here:

Disclaimer: The opinions expressed in this article belong to the author. Indic Today is neither responsible nor liable for the accuracy, completeness, suitability, or validity of any information in the article.